Precision machining technology involves producing high-accuracy parts using advanced tools and techniques, ensuring minimal tolerances and superior surface finishes, critical in modern manufacturing and engineering applications.

1.1 Overview of Precision Machining

Precision machining is a specialized manufacturing process that produces high-accuracy parts with tight tolerances. It involves advanced techniques like milling, turning, and grinding to achieve precise dimensions and surface finishes. Utilizing cutting-edge tools and materials, precision machining serves industries such as aerospace, automotive, and healthcare, where exact specifications are critical. The process requires skilled operators and sophisticated machinery to ensure consistency and quality, making it indispensable in modern engineering and production environments.

1.2 Importance of Precision in Modern Manufacturing

Precision is vital in modern manufacturing as it ensures product reliability, safety, and performance. In industries like aerospace and healthcare, even minor deviations can lead to critical failures. High precision reduces waste, enhances efficiency, and meets stringent regulatory standards. It also drives innovation, enabling the creation of complex components for advanced technologies. By minimizing errors and maximizing consistency, precision machining contributes significantly to global competitiveness and technological advancement, making it a cornerstone of modern industrial practices and innovation.

1.3 Brief History of Machining Technology

Machining technology traces its roots to ancient civilizations, where basic tools were used to shape materials. The Industrial Revolution marked a significant leap with the invention of lathes and milling machines. The 20th century introduced CNC machining, enabling precision and automation. Modern advancements include CAD/CAM software, high-speed machining, and advanced materials. This evolution has transformed machining from craftsmanship to a highly precise, technology-driven process, essential for producing complex components across industries, ensuring accuracy, efficiency, and innovation in manufacturing.

Fundamental Principles of Precision Machining

Precision machining relies on precise tool geometry, rigid machine tools, and controlled processes to achieve tight tolerances and high surface quality, ensuring part accuracy and functionality.

2.1 Basic Concepts of Machining Processes

Machining processes involve removing material from a workpiece to achieve desired dimensions and surface quality. Key operations include turning, milling, drilling, and grinding. Each process uses specific tools and techniques to ensure precision and accuracy. Material removal rates, tool geometry, and cutting parameters like speed and feed are critical factors. Understanding these fundamentals is essential for optimizing machining operations and producing high-quality components efficiently.

2.2 Key Factors Influencing Machining Accuracy

Machining accuracy is influenced by tool geometry, machine tool rigidity, and cutting parameters. Tool wear, thermal expansion, and vibration also impact precision. High-quality cutting tools and stable machining conditions minimize errors, ensuring dimensional accuracy and surface finish. Advanced CNC systems and precise control of feed rates and spindle speeds further enhance accuracy, making them critical in achieving tight tolerances required in precision machining.

2.3 Role of Machine Tools in Precision Machining

Machine tools are central to precision machining, enabling precise material removal and shaping. Modern CNC machines, with their high rigidity and advanced control systems, ensure accurate and repeatable results. They support various operations like milling, turning, and grinding, while automation enhances efficiency. High-performance machine tools are essential for meeting stringent tolerances and producing complex geometries, making them indispensable in industries requiring high-precision components.

Machining Processes and Techniques

Machining processes involve cutting, shaping, and finishing materials with precision tools. Techniques range from conventional methods like turning and milling to advanced CNC and EDM processes, ensuring high accuracy and efficiency in manufacturing.

3.1 Conventional Machining Processes

Conventional machining processes include traditional techniques like turning, milling, and drilling. These methods use physical cutting tools to remove material and shape workpieces. Turning involves rotating the workpiece while a tool cuts it, while milling uses a rotating cutter to remove material. Drilling creates holes using twist drills. These processes are foundational in precision machining, offering simplicity and effectiveness for basic geometries. However, they may lack the precision and complexity achievable with advanced techniques, making them suitable for straightforward applications.

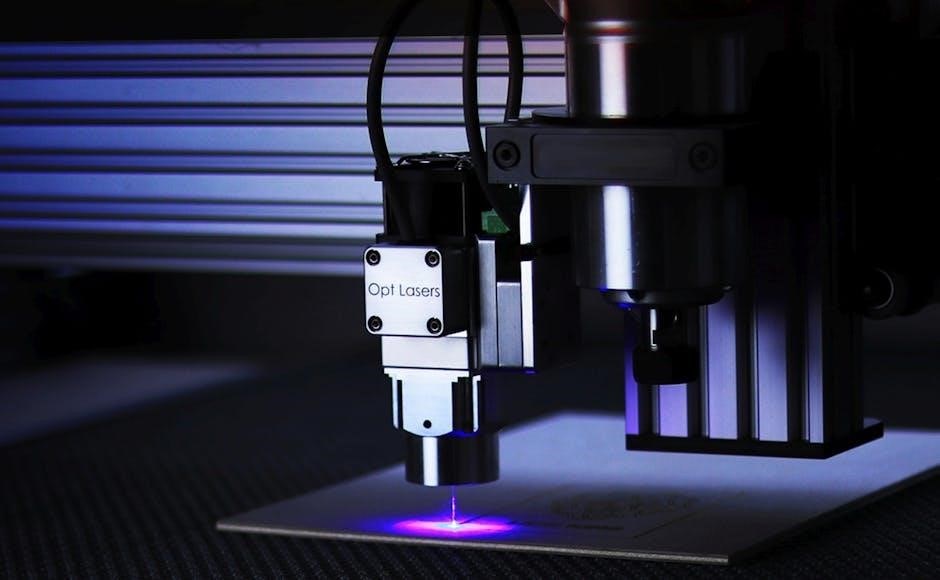

3.2 Advanced Machining Techniques

Advanced machining techniques include methods like CNC machining, EDM, and laser cutting. These processes utilize cutting-edge technology to achieve high precision and complex geometries. CNC machining employs computerized controls for accurate tool movements, while EDM uses electrical discharges to erode material. Laser cutting offers high-speed, precise cuts with minimal material waste. These techniques are essential for producing intricate parts in industries requiring tight tolerances, such as aerospace and medical devices, where conventional methods fall short in delivering the necessary accuracy and detail.

3.3 Comparison of Different Machining Methods

Different machining methods vary in precision, cost, and application. Conventional methods like milling and turning are cost-effective for simple parts, while advanced techniques such as EDM and laser machining excel in producing complex geometries. CNC machining offers high accuracy and automation, making it ideal for large-scale production. Each method has unique advantages, and selecting the right one depends on factors like material type, desired tolerances, and production volume, ensuring optimal results in precision machining applications.

Cutting Tools and Materials

Cutting tools and materials are crucial in precision machining, with options like carbide and diamond tools offering durability and accuracy, ensuring optimal machining performance and longevity.

4.1 Types of Cutting Tools

Cutting tools in precision machining include turning tools, milling cutters, drills, and grinding wheels. Each type is designed for specific operations, ensuring precise material removal and surface quality. Turning tools shape workpieces by removing material, while milling cutters create complex geometries. Drills and grinding wheels are used for hole-making and finishing. The selection of the right tool depends on the material, operation, and desired outcome, ensuring efficiency and accuracy in manufacturing processes.

4.2 Materials Used in Cutting Tools

Cutting tools are made from high-speed steel (HSS), tungsten carbide, and cubic boron nitride (CBN). HSS offers durability and cost-effectiveness for general machining. Tungsten carbide is harder and wear-resistant, ideal for high-speed operations. CBN excels in machining hard ferrous materials. These materials are often coated with titanium nitride or alumina to enhance performance and extend tool life, ensuring precision and efficiency in various machining applications.

4.3 Tool Geometry and Its Impact on Machining

Tool geometry significantly influences machining efficiency and accuracy. Rake angle, clearance angle, and nose radius are critical factors. A positive rake angle enhances cutting efficiency but reduces tool strength, while a negative rake increases durability. Clearance angle prevents tool-workpiece contact, minimizing wear. Nose radius affects surface finish and tool life. Proper geometry optimizes cutting forces, heat generation, and chip formation, ensuring precise machining. Advanced geometries, like variable flute designs, improve performance in challenging materials, enhancing overall machining outcomes and tool longevity.

Metrology and Quality Control

Metrology ensures precision machining accuracy through advanced measurement tools like calipers and CMMs. Quality control involves rigorous inspections and certifications to maintain high standards and reliability in final products.

5.1 Importance of Metrology in Precision Machining

Metrology is crucial in precision machining as it ensures dimensional accuracy and surface quality. Advanced tools like coordinate measuring machines (CMMs) and optical scanners verify tight tolerances, reducing errors. By implementing metrology, manufacturers maintain consistency, comply with standards, and enhance product reliability. It also supports process optimization, minimizing waste and improving efficiency. Accurate measurements enable traceability, critical for industries like aerospace and healthcare, where precision directly impacts performance and safety.

5.2 Common Metrology Instruments and Techniques

Common metrology instruments include coordinate measuring machines (CMMs), optical comparators, and laser scanners. Techniques like touch probing and non-contact scanning ensure precise measurements. CMMs are widely used for complex geometries, while optical comparators excel in profile and surface inspections. Laser scanning offers rapid data acquisition for large components. These tools enhance accuracy, enabling precise part verification and process control, which are vital for maintaining quality in precision machining operations across various industries.

5.3 Quality Control Measures in Machining

Quality control in machining involves rigorous inspection protocols, statistical process control (SPC), and first article inspections. SPC monitors production variability, ensuring consistency. First article inspections verify initial parts meet specifications. Regular tool calibration and maintenance prevent deviations. Operators use checklists and visual aids to maintain standards. Corrective actions address defects promptly, minimizing waste. These measures ensure high-quality output, customer satisfaction, and compliance with industry standards, fostering operational excellence and reliability in precision machining environments.

CNC Machining and Automation

CNC machining and automation revolutionize modern manufacturing by integrating computerized controls and advanced workstations like Dell Precision, ensuring high-precision, efficient, and scalable production processes.

6.1 Basics of CNC Machining

CNC machining utilizes computerized controls to operate machine tools, enabling precise and automated manufacturing. It relies on G-code instructions to guide cutting tools, ensuring accuracy and consistency. Modern CNC systems, supported by high-performance workstations like Dell Precision, optimize production processes. This technology is integral to producing complex geometries and high-tolerance parts, making it indispensable in industries like aerospace and automotive. CNC machining enhances efficiency, scalability, and quality, driving innovation in precision engineering and manufacturing.

6.2 Advantages of CNC Over Traditional Machining

CNC machining offers superior precision, consistency, and efficiency compared to traditional methods. It minimizes human error, enabling repeatable high-quality outputs. CNC systems, supported by advanced workstations like Dell Precision, allow for complex geometries and rapid production. Automation reduces labor costs and increases throughput, making CNC ideal for large-scale manufacturing. Additionally, CNC’s ability to handle diverse materials and intricate designs ensures versatility, driving its adoption across industries requiring high-accuracy components, such as aerospace and automotive.

6.3 Role of Automation in Modern Machining

Automation revolutionizes machining by integrating AI, IoT, and CNC systems, enhancing efficiency and precision. It streamlines production workflows, reduces manual intervention, and optimizes resource utilization. Advanced workstations, like Dell Precision, support complex simulations and real-time monitoring, ensuring high-quality outputs. Automation also enables predictive maintenance, minimizing downtime and extending equipment lifespan. By leveraging automation, manufacturers achieve scalability, consistency, and cost-effectiveness, making it indispensable in modern machining for industries like aerospace and automotive, where precision and reliability are paramount.

Applications of Precision Machining

Precision machining is vital in aerospace, automotive, and medical sectors, producing lightweight components, high-performance parts, and biocompatible devices with tight tolerances, enabling innovation across industries.

7.1 Aerospace Industry

The aerospace industry relies heavily on precision machining to fabricate lightweight, high-strength components such as engine parts, turbine blades, and satellite components. These parts must meet stringent tolerances and durability requirements to ensure safety and performance at extreme conditions. Advanced machining techniques, including CNC milling and turning, are employed to achieve the necessary precision. Materials like titanium and advanced composites are commonly used, requiring specialized cutting tools and processes. The sector’s demand for precision drives continuous innovation in machining technology, ensuring reliability in critical applications.

7.2 Automotive Industry

The automotive industry utilizes precision machining to produce high-performance engine components, gear systems, and braking mechanisms. Tight tolerances ensure fuel efficiency, reduced emissions, and enhanced vehicle safety. CNC machining and advanced tooling enable the production of complex parts like cylinder blocks and camshafts. Lightweight materials, such as aluminum and carbon fiber, are increasingly machined to improve vehicle dynamics. Precision machining plays a pivotal role in meeting the industry’s demands for reliability, sustainability, and innovation, driving advancements in both electric and traditional vehicles.

7.3 Medical and Healthcare Sector

Precision machining is critical in the medical sector for producing intricate surgical instruments, implantable devices, and diagnostic equipment. High-precision components, such as orthopedic implants and dental instruments, require tight tolerances for patient safety and effectiveness. CNC machining enables the creation of complex geometries in materials like titanium and stainless steel, which are biocompatible. Advanced techniques ensure miniaturization and customization, leading to improved patient outcomes and innovative treatments. The sector relies heavily on precision machining for reliability, sterility, and performance in life-saving applications.

7.4 Other Industrial Applications

Precision machining serves various industries beyond aerospace, automotive, and healthcare. In the energy sector, it produces turbine components and nuclear reactor parts. Telecommunications rely on it for creating satellite and fiber optic components. Consumer goods benefit from high-precision machining in manufacturing electronics, watches, and optical devices. Additionally, precision machining is essential for producing molds, dies, and tooling used across multiple industries. Its versatility ensures high-quality, customized solutions, driving innovation and efficiency in diverse industrial applications globally.

Industry Trends and Innovations

Precision machining is embracing AI, IoT, and automation, enhancing efficiency and reducing waste. Sustainable practices and green technologies are becoming integral to modern manufacturing processes.

8.1 Emerging Technologies in Machining

Emerging technologies like AI, IoT, and automation are revolutionizing precision machining. AI optimizes machining parameters, reducing waste and improving accuracy. IoT enables real-time monitoring and predictive maintenance, enhancing efficiency. Advanced CNC systems integrate seamlessly with these technologies, ensuring precise and repeatable results. Green machining technologies are also gaining traction, focusing on energy efficiency and sustainable practices. These innovations are driving the industry toward smarter, faster, and more environmentally friendly manufacturing solutions, setting new standards for precision and performance.

8.2 Sustainability in Precision Machining

Sustainability in precision machining focuses on reducing environmental impact through eco-friendly practices. Techniques like dry machining and minimum quantity lubrication minimize chemical use. Energy-efficient machine tools and recycling programs for metal waste are increasingly adopted. Sustainable materials and coatings are also being explored to reduce resource consumption. These practices not only lower operational costs but also align with global environmental standards, making precision machining more responsible and future-ready. Sustainability is becoming a key driver in modern manufacturing strategies.

8.3 Impact of AI and IoT on Machining Processes

AI and IoT are revolutionizing machining processes by enabling predictive maintenance, optimizing tool performance, and improving accuracy. AI algorithms analyze data to predict tool wear and minimize downtime. IoT connects machines, allowing real-time monitoring and remote control. These technologies enhance efficiency, reduce waste, and improve product quality. AI-driven systems also optimize machining parameters, leading to faster production cycles. The integration of AI and IoT is transforming traditional machining into a smarter, more connected, and efficient industry, ensuring competitiveness in a rapidly evolving market.

Environmental and Safety Considerations

Precision machining requires minimizing waste and using eco-friendly coolants. Safety measures include proper ventilation and protective gear to prevent accidents and exposure to harmful substances.

9.1 Environmental Impact of Machining Processes

Precision machining processes can generate significant environmental impacts, including metal waste, coolant disposal, and energy consumption. Proper waste management and recycling are essential to minimize ecological damage. Using eco-friendly cutting fluids and optimizing machining parameters can reduce harmful emissions. Additionally, adopting sustainable practices like dry machining or minimum quantity lubrication helps conserve resources and lowers the carbon footprint of manufacturing operations.

9.2 Safety Measures in Machining Operations

Safety is paramount in machining operations to prevent accidents and ensure a secure working environment. Proper use of personal protective equipment, such as safety glasses and gloves, is essential. Regular maintenance of machinery and adherence to operational guidelines reduce risks. Training programs and emergency protocols further enhance safety standards, protecting both personnel and equipment from potential hazards.

9.3 Waste Management and Recycling in Machining

Efficient waste management and recycling are critical in machining to minimize environmental impact. Metal scraps and coolants are commonly recycled, reducing resource depletion. Proper disposal of hazardous materials prevents pollution. Implementing recycling programs and using eco-friendly practices contribute to sustainable machining operations, aligning with environmental regulations and promoting a greener industry.

Case Studies and Real-World Examples

Real-world applications of precision machining are evident in aerospace, automotive, and medical industries, showcasing its role in producing high-precision components essential for advanced technologies and innovations.

10.1 Successful Implementation of Precision Machining

Precision machining has been successfully implemented in various industries, such as aerospace and automotive, to produce high-accuracy components. Companies utilizing advanced CNC machines and CAD/CAM software have achieved significant reductions in material waste and production time. For instance, in the aerospace sector, precision machining enables the creation of complex engine parts with tight tolerances, ensuring reliability and performance. Similarly, in the automotive industry, it facilitates the manufacturing of high-precision gears and bearings, improving vehicle efficiency and durability. These implementations highlight the critical role of precision machining in modern manufacturing, driving innovation and operational efficiency across sectors.

10.2 Challenges and Solutions in Real-World Scenarios

In real-world precision machining, common challenges include material waste, complex geometries, and tight tolerances. To address these, manufacturers optimize CNC programming and utilize advanced cutting tools. Additionally, integrating automation and IoT enhances process monitoring and reduces errors. For instance, aerospace companies employ specialized coatings and cooling systems to maintain precision in high-temperature environments. These solutions ensure high-quality outputs while minimizing operational inefficiencies, demonstrating the adaptability of precision machining in diverse industrial applications.

10.3 Benchmarking Best Practices

Benchmarking best practices in precision machining involves comparing processes and outcomes against industry standards and competitors. Key activities include performance assessments, tooling evaluations, and workflow optimizations. Adopting advanced technologies, such as CNC machining and automation, enhances efficiency. Continuous improvement strategies, like lean manufacturing, reduce waste and improve accuracy. Regular audits and feedback loops ensure sustained quality. By aligning with industry benchmarks, manufacturers achieve operational excellence, delivering high-precision products consistently while maintaining cost-effectiveness and scalability in diverse applications.

Future Outlook and Developments

The future of precision machining lies in technological advancements, with AI and IoT enhancing processes, and sustainable practices driving innovation in tooling and materials.

11.1 Predictions for the Evolution of Machining Technology

The evolution of machining technology is expected to be driven by advancements in AI, IoT, and automation, leading to smarter, more efficient processes. Robotics and unmanned systems will likely dominate, reducing human intervention. Sustainable practices will gain prominence, with a focus on eco-friendly materials and energy-efficient machining. Additionally, the integration of real-time data analytics will enable predictive maintenance and optimized production workflows, ensuring higher precision and reduced downtime in manufacturing.

11.2 Potential Breakthroughs in Tooling and Materials

Future advancements in tooling and materials may include the development of ultra-durable, high-performance cutting tools made from advanced composites and nanomaterials. These innovations could significantly improve machining efficiency and reduce wear. Additionally, sustainable materials and coatings might emerge, offering enhanced thermal resistance and environmental benefits. Such breakthroughs would enable manufacturers to achieve higher precision and longer tool lifespans, driving cost savings and operational excellence across various industries.

11.3 The Role of Precision Machining in Future Industries

Precision machining will play a pivotal role in shaping future industries, particularly in sectors like aerospace, healthcare, and renewable energy. As demand for miniaturized, complex components grows, advanced machining techniques will enable the production of high-precision parts essential for next-generation technologies. The integration of AI and IoT in machining processes will further enhance efficiency and customization, ensuring that precision machining remains a cornerstone of innovation and industrial progress in the years to come.

Conclusion

Precision machining technology is critical for modern industries, driving innovation and enabling the production of high-precision components essential for advancements in aerospace, healthcare, and renewable energy sectors.

12.1 Summary of Key Points

Precision machining technology is a cornerstone of modern manufacturing, enabling the creation of high-precision components with minimal tolerances. It integrates advanced tools, materials, and techniques to meet the demands of industries like aerospace, automotive, and healthcare. The evolution of CNC machining and automation has enhanced accuracy and efficiency, while emerging technologies such as AI and IoT continue to shape the future of machining. Sustainability and quality control remain critical, ensuring environmental responsibility and adherence to global standards, driving innovation and excellence in precision machining applications.

12.2 Final Thoughts on the Importance of Precision Machining

Precision machining is indispensable in driving innovation and excellence across industries, enabling the production of intricate, high-performance components. Its role in advancing technologies, from aerospace to healthcare, underscores its critical importance in modern manufacturing. As industries evolve, the demand for precision machining will continue to grow, necessitating skilled professionals and cutting-edge techniques to meet the challenges of tomorrow.